Flexibility and printability are key in paper, cloth, and tape applications – but when tensile strength and durability are necessary too, you don’t want your product’s design to take a hit. That’s precisely the kind of issue that CLAF® nonwovens can address! With a flat profile, easy lamination, and balanced tear resistance, CLAF® provides powerful reinforcement to meet a wide variety of criteria. Discover how you can create a high-performance product with this innovative material, read on or reach out to learn more.

Easy Reinforcement With CLAF®

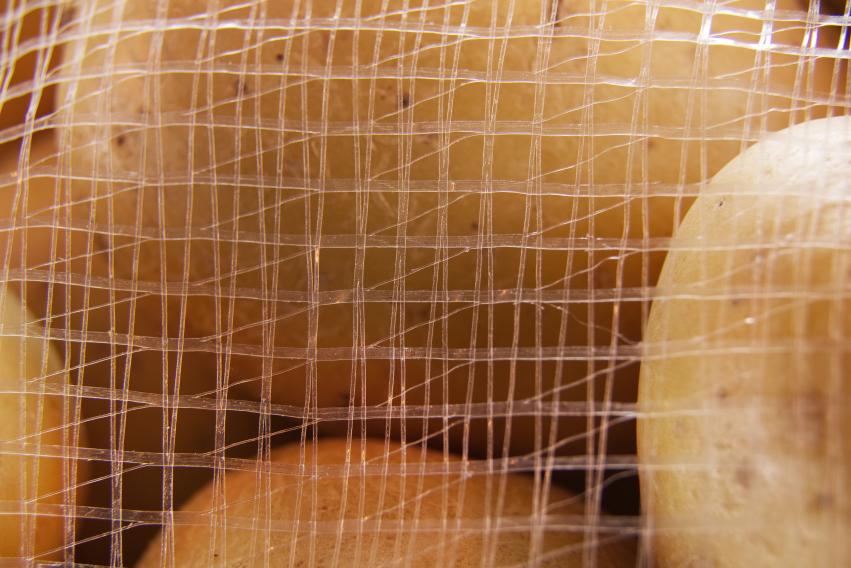

CLAF®’s original mesh structure and unique composition make it ideal for composites! It can be combined with materials of all kinds, and strong dimensional stability means that it holds together through a variety of processes. It can be combined with other materials through thermal lamination, sonic bonding, powder application, extrusion lamination, and adhesive lamination. We even offer converting services to make it easier to get a material with exactly the qualities you need, and help you develop a process to consistently produce the material you want.

Creating Performance Materials With CLAF®

What’s so special about CLAF®-backed materials? In tapes, it’s light but provides stiffness and strength. Its cross-laminated mesh allows for clean, straight tears without cutting – perfect for construction, packaging, and other applications. But – with the right lamination method – CLAF® provides tear-resistance in performance cloth materials like automotive seating reinforcement, furniture, and everyday shopping bags. And, with simple extrusion lamination, CLAF® turns kraft paper into a specialty industrial-strength material, without compromising printability. No special ink or machinery is necessary to produce high-quality prints on CLAF®-reinforced paper.

Composite Applications and Benefits

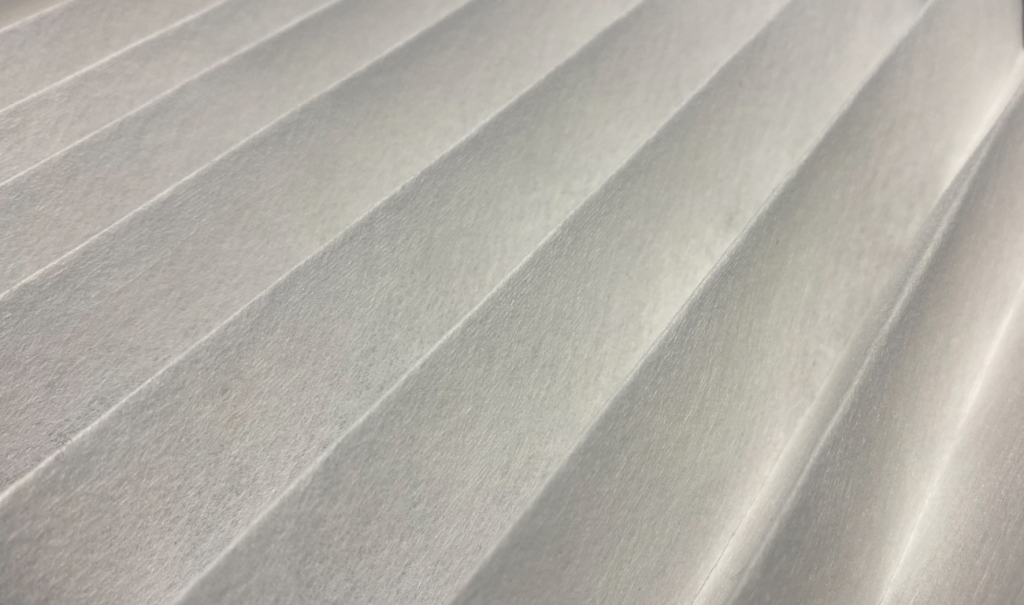

Other nonwovens work well with CLAF®, as do industrial films. Combined with other nonwovens, CLAF®’s highly porous surface increases strength and tear resistance, while still allowing air or water to pass through. One-pass adhesive lamination is also possible with other nonwovens thanks to the open structure of CLAF®. No matter how it’s bonded to industrial films, CLAF® adds minimal weight and bulk. It processes like a film, too, so it can be incorporated easily into film lines.

CLAF® and CLAF® Bio Fabric™

And, for eco-conscious companies and consumers, there’s a version of CLAF® with all of those benefits that’s made from sustainably-sourced sugarcane! CLAF® Bio Fabric™ has the same structure and profile as original CLAF®, it bonds with a wide variety of materials, heat-seals to itself, and is easy to process. To learn more about this environmentally-responsible alternative, visit clafbio.com. To find out about using either CLAF® or CLAF® Bio Fabric™ in your application, reach out and let’s talk about what properties would best meet your needs.